Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Explore the revolutionary world of digital dentures! Learn how 3D imaging and CAD/CAM technology create precise, comfortable, and efficient denture solutions.

Imagine a world where getting new dentures is as easy as printing a photograph. Welcome to the realm of digital dentures! As dental technology advances, digital dentures are revolutionizing the way we restore smiles.

Unlike traditional dentures, which require multiple fittings and adjustments, digital dentures are designed using cutting-edge 3D imaging and CAD/CAM technology.

This ensures a precise fit, enhanced comfort, and a quicker turnaround time. Plus, the digital design allows for easy adjustments and replacements in the future. In this article, we’ll delve into how digital dentures work, explore their benefits, and explain why they might be the perfect solution for you.

Whether you’re considering dentures for the first time or looking to upgrade, digital dentures offer a modern, efficient alternative. Ready to transform your smile? Let’s get started!

The field of dentistry has come a long way in the development and improvement of dentures. Historically, Digital Dentures were crafted using a variety of materials such as animal teeth, ivory, and even human teeth. However, these traditional dentures were often uncomfortable, ill-fitting, and lacked the natural appearance that patients desired.

In recent years, the introduction of digital dentures has revolutionized the way dentures are designed and fabricated. Digital dentures utilize advanced technology, such as computer-aided design and manufacturing (CAD/CAM), to create precise and customized solutions for patients. This digital approach allows for a more accurate fit, improved aesthetics, and enhanced patient satisfaction. By harnessing the power of digital technology, dentists are now able to provide patients with dentures that look and feel more natural than ever before.

Digital dentures have revolutionized the field of dentistry by offering improved accuracy and fit compared to traditional dentures. This technological advancement has been made possible through the use of computer-aided design and manufacturing (CAD/CAM) technology. By scanning the patient’s oral cavity and creating a precise digital model, dentists can now design dentures that perfectly fit the contours of the patient’s mouth.

The improved accuracy and fit of digital dentures can be attributed to the elimination of human error. Traditional dentures are made by taking impressions of the patient’s mouth using messy and often uncomfortable materials. These impressions are then sent to a dental laboratory where technicians manually create the dentures. This process is susceptible to errors and inaccuracies, leading to ill-fitting dentures that can cause discomfort and oral health problems. With digital dentures, the entire workflow is streamlined and automated, ensuring a precise fit that enhances both comfort and function for the patient.

| Benefits of Digital Dentures |

|---|

| Traditional Dentures | Digital Dentures |

|---|---|

| Time-consuming process | Streamlined process |

| Manual impression-taking | Digital impression-taking |

| Greater chance of inaccuracies | Higher precision in fit |

| Multiple appointments for adjustments | Fewer appointments for adjustments |

| Less control over aesthetics | More control over aesthetics |

| Limited customization options | Enhanced customization options |

| Prone to wear and tear | Improved durability |

| Requires physical storage | Can be stored digitally |

| May require re-making due to wear | Can be easily replicated digitally |

| More difficult to make adjustments | Allows for easier adjustments |

Step 1: Digital Impression

Step 2: Denture Design

Step 3: Fabrication

Step 4: Finishing and Polishing

Step5: Advantages of Digital Dentures

When it comes to digital denture design, one of the key advantages is the ability to create customized solutions for each individual patient. This level of personalization ensures a better fit, improved comfort, and enhanced functionality. Traditional dentures often require multiple adjustments and modifications to achieve the desired fit, while digital denture design allows for precise customization from the start.

With digital denture design, dentists can utilize advanced software and 3D imaging technology to capture detailed impressions of the patient’s oral anatomy. This data is then used to create a virtual model of the denture, which can be carefully adjusted and refined to meet the specific needs and preferences of the patient. By working closely with the patient and leveraging digital tools, dentists can ensure that the final denture design is tailored to their unique oral structure and delivers optimal results. Such personalized solutions not only improve the overall comfort and function of the denture but also enhance the patient’s self-confidence and quality of life.

3D scanning has revolutionized the field of digital dentures by providing an efficient and precise method for capturing a patient’s oral anatomy. This technology allows dentists to create highly accurate digital models of the patient’s mouth, which can then be used to design custom dentures. The 3D scanning process involves using a specialized scanner to capture detailed images of the patient’s oral cavity, including the shape and contours of their gums and remaining teeth.

One of the main advantages of 3D scanning in digital dentures is its ability to capture a high level of detail. Traditional methods of taking impressions, such as using putty-like materials, can sometimes lead to distortions or inaccuracies in the resulting mold. With 3D scanning, the dentist can obtain a precise digital replica of the patient’s oral anatomy, ensuring a more accurate fit for their dentures.

This leads to improved comfort and functionality for the patient, as well as a more natural and aesthetic appearance. Additionally, 3D scanning allows for greater efficiency in the denture fabrication process, reducing the number of appointments required and minimizing the potential for human error. With these benefits in mind, it is clear that 3D scanning plays a crucial role in the development and production of digital dentures.

Digital denture manufacturing is revolutionizing the way dentures are produced, offering patients a more precise and efficient process. From design to production, this innovative technology streamlines the traditional denture manufacturing process and improves overall patient outcomes.

The first step in digital denture manufacturing is taking a digital scan of the patient’s oral cavity using advanced 3D scanning techniques. This scan captures the exact shape and dimensions of the patient’s mouth, eliminating the need for messy and uncomfortable impression materials. The digital scan is then sent to the computer-aided design (CAD) software, where the denture design process begins.

Using the CAD software, dental professionals can create customized denture designs that cater to each patient’s unique needs and preferences. This includes selecting the appropriate tooth shape, size, and color, as well as ensuring proper fit and functionality. Once the design is finalized, it is sent to a computer-aided manufacturing (CAM) system for production.

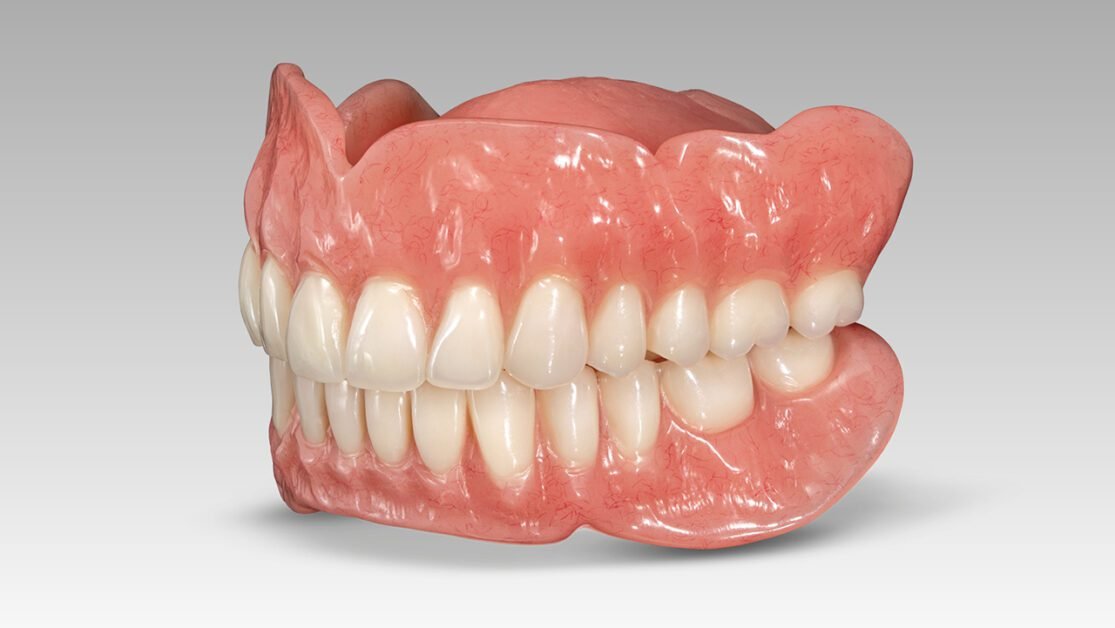

The CAM system uses state-of-the-art milling machines to carve out the denture base and tooth shapes from a solid block of biocompatible material. This automated process ensures accuracy and consistency in the manufacturing process, resulting in dentures that fit comfortably and function optimally. After the milling process, any necessary adjustments and finishing touches are made to ensure the denture meets the patient’s expectations.

Overall, digital denture manufacturing offers numerous benefits over traditional methods, including improved accuracy, fit, and customization. By leveraging advanced technology and computerized systems, dental professionals can confidently provide patients with dentures that are precisely tailored to their unique oral anatomy. With the increasing adoption of digital denture manufacturing, patients can expect an enhanced denture experience that combines aesthetics, comfort, and functionality.

Digital dentures have revolutionized the field of dentistry, providing a range of materials options that offer enhanced strength, durability, and aesthetics. One popular material used in digital dentures is acrylic resin. Acrylic resin offers excellent color stability, making it a suitable choice for patients seeking natural-looking dentures. It is also lightweight, which ensures maximum comfort for the wearer. Additionally, acrylic resin is highly customizable, allowing dentists to create dentures that perfectly match the patient’s oral anatomy.

Another material option for digital dentures is a hybrid composite resin. This material combines the strength of acrylic resin with the esthetics of ceramics, resulting in dentures that are not only durable but also highly esthetic. The hybrid composite resin offers superior fracture resistance, making it an ideal choice for patients who require extra durability. Moreover, it allows for easy adjustments and repairs, minimizing the need for frequent visits to the dentist.

Apart from acrylic resin and hybrid composite resin, other materials like polymethyl methacrylate (PMMA), zirconia, and nanoceramics are also used in digital dentures. Each material has its own unique set of advantages, such as improved biocompatibility, enhanced stain resistance, or increased strength. The choice of material depends on various factors, including the patient’s specific needs, budget, and aesthetic preferences.

As technology continues to advance, we can expect further innovations in the materials used for digital dentures. Researchers are constantly exploring new materials that offer better performance, improved esthetics, and increased longevity. By staying up to date with the latest advancements, dentists can provide their patients with the best possible solutions for their denture needs.

Achieving a proper fit is crucial when it comes to digital dentures. Unlike traditional dentures, which can often be uncomfortable and require constant adjustments, digital dentures offer a more precise and comfortable fit. This is because digital dentures are customized to each individual patient using advanced technology, ensuring a higher level of accuracy and fit.

A properly fitted digital denture not only improves overall comfort, but it also enhances functionality. With a snug and secure fit, patients can confidently eat, speak, and smile without worrying about their dentures slipping or moving. This can greatly improve their quality of life and help them regain their confidence.

Moreover, proper fit is essential for maintaining optimal oral health. Ill-fitting dentures can cause irritation, sore spots, and even lead to bone loss over time. Digital dentures, on the other hand, are designed to fit precisely and comfortably, reducing the risk of these complications. By prioritizing proper fit, patients can ensure the longevity and effectiveness of their digital dentures, ultimately enjoying a healthier and more comfortable oral experience.

| Aspect | Importance |

|---|---|

| Comfort | Proper fit ensures comfort during wearing. |

| Functionality | Facilitates normal chewing and speaking. |

| Stability | Prevents slippage and discomfort. |

| Oral Health | Maintains gum health and prevents sores. |

| Longevity of Dentures | Proper fit extends the life of dentures. |

| Confidence | Boosts self-confidence in social situations. |

| Speech Clarity | Aids in clear pronunciation of words. |

| Prevention of Bone Loss | Helps maintain bone structure in the jaw. |

| Prevention of Ulcers | Reduces the risk of oral ulcers and lesions. |

Enhancing the aesthetics of dentures has always been a top priority in the field of dentistry. With the advent of digital dentures, the ability to customize the color and shape of dentures has reached new heights. Digital technology allows dentists to precisely match the color of the denture teeth to the natural shade of the patient’s remaining teeth. This not only enhances the overall appearance of the dentures but also provides a more natural and seamless blend with the patient’s existing dentition.

Moreover, digital dentures offer the flexibility to customize the shape of the denture teeth according to the patient’s facial structure and preferences. Dentists can now create dentures that mimic the patient’s natural smile, ensuring a comfortable and natural-looking result. This level of customization not only improves the aesthetics of the dentures but also boosts the patient’s confidence and self-esteem.

In conclusion, digital dentures have revolutionized the field of dentistry by offering unparalleled customization options for enhancing the aesthetics of dentures. The ability to precisely match the color of the denture teeth and customize the shape according to the patient’s facial structure has transformed the way dentures are designed and fabricated. With digital dentures, patients can now enjoy dentures that look and feel like their natural teeth, ensuring a more comfortable and confident smile.

Digital dentures and traditional dentures are two different options available for individuals who require dental prosthetics. While both serve the purpose of restoring missing teeth, there are distinct differences between the two.

Traditional dentures, also known as removable dentures, have been in use for many years. They are typically made from acrylic and rely on the shape of the patient’s gums and jaw to remain in place. The process of creating traditional dentures involves taking impressions of the patient’s mouth, which are then used to create a mold for the dentures. This mold is sent to a dental laboratory, where the final denture is crafted.

On the other hand, digital dentures, also known as CAD/CAM dentures, utilize advanced computer technology to design and manufacture the prosthetic. This technology allows for a more precise fit and improved aesthetics. Digital dentures are created by scanning the patient’s mouth, which generates a 3D model. This model is then used to design the denture, which is milled from a block of material using a computerized milling machine.

The use of digital dentures offers several advantages over traditional dentures. The digital design process allows for customized solutions that can cater to each patient’s unique oral anatomy. Additionally, digital dentures offer improved accuracy and fit, resulting in increased comfort for the wearer. The ability to digitally adjust and modify the denture design also provides flexibility and convenience in terms of adjustments and revisions.

It is important to note that the choice between digital dentures and traditional dentures ultimately depends on the individual’s specific needs and preferences. Consulting with a dental professional is crucial to determine the most suitable option for each patient. As technology continues to advance, the field of digital dentistry holds promising potential for further advancements in dental prosthetics.

CAD/CAM technology has revolutionized the field of digital dentures, offering numerous benefits for both patients and dental professionals. With the use of computer-aided design (CAD) and computer-aided manufacturing (CAM), dentists can now create highly precise and customized dentures that fit comfortably and function effectively.

One of the key advantages of CAD/CAM technology in digital dentures is the improved accuracy in design and production. Through the use of advanced 3D scanning technology, dentists can capture detailed images of the patient’s oral cavity, allowing for a more precise and accurate digital representation. This digital model is then used to design the denture, taking into consideration factors such as bite alignment, occlusion, and aesthetics. The use of CAD software enables dentists to customize the denture based on the patient’s unique oral anatomy, resulting in a better fit and improved comfort. Additionally, the CAM technology in digital dentures allows for precise and efficient manufacturing, reducing the margin for error and ensuring a higher quality end product.

By incorporating CAD/CAM technology into the workflow of digital dentures, dental professionals can enhance the overall patient experience. The ability to create highly accurate and customized dentures allows for improved oral function and aesthetics, which can greatly benefit the patient’s quality of life.

Moreover, the streamlined manufacturing process offered by CAD/CAM technology reduces the turnaround time for denture production, enabling patients to receive their new dentures in a shorter period. This leads to increased patient satisfaction and convenience, as well as improved efficiency for dental practices. Overall, the role of CAD/CAM technology in digital dentures cannot be overstated, as it offers precise customization, improved accuracy, and enhanced patient outcomes.

One of the key advantages of digital dentures is the flexibility and convenience they offer when it comes to adjustments. Unlike traditional dentures, which may require multiple visits to the dentist for adjustments and readjustments, digital dentures can be easily modified to ensure a perfect fit for the patient. The digital workflow allows for precise adjustments to be made based on the patient’s feedback and comfort level, resulting in a customized fit that enhances overall oral health.

The convenience of digital denture adjustments is particularly beneficial for pediatric patients, who may require frequent modifications as their mouth and jaw continue to develop. With digital dentures, dentists can quickly and accurately make necessary adjustments to accommodate the changes in a child’s oral structure. This not only saves time for both the dentist and the patient, but also minimizes discomfort and ensures optimal oral health for growing children. The flexibility offered by digital dentures allows for efficient and precise adjustments, making the process more comfortable and convenient for patients of all ages.

Digital dentures offer a remarkable level of durability and longevity compared to traditional dentures. The advanced materials and manufacturing techniques used in digital dentures have significantly improved their lifespan, ensuring they can withstand the daily wear and tear of normal usage.

One of the key factors contributing to the durability of digital dentures is the precision of the manufacturing process. CAD/CAM technology allows for highly accurate and precise fabrication, resulting in a better fit and alignment of the dentures. This precise fit helps to distribute the forces of chewing evenly across the denture, reducing the risk of fractures and breakages.

Furthermore, digital dentures are typically made from high-quality materials that are known for their strength and resilience. These materials, such as biocompatible polymers and nanocomposites, are designed to withstand the forces exerted during chewing and speaking. They are also resistant to staining, discoloration, and degradation, ensuring that the dentures maintain their appearance and functionality over time.

In addition to their durability, digital dentures also have an impressive level of longevity. With proper care and maintenance, these dentures can last for many years without significant deterioration. Regular dental check-ups and professional cleanings, along with proper oral hygiene at home, are essential for preserving the longevity of digital dentures.

Overall, the durability and longevity of digital dentures make them a highly desirable option for patients seeking a reliable and long-lasting solution to their dental needs. By investing in digital dentures, individuals can enjoy the benefits of a comfortable and durable tooth replacement option that will last for many years to come.

Digital dentures have revolutionized the field of dentistry, but one common concern among patients is the cost. Are digital dentures worth the investment? Let’s take a closer look at the financial aspect of this innovative technology.

While digital dentures may have a higher upfront cost compared to traditional dentures, they offer several long-term benefits that make them a worthwhile investment. One of the key advantages is improved accuracy and fit. Digital denture design allows for precise measurements and customization, ensuring a comfortable and secure fit for the patient. This eliminates the need for multiple adjustments and reduces the risk of discomfort or ill-fitting dentures in the future. Moreover, the precise fit of digital dentures can contribute to better oral health by preventing issues like gum irritation and bone loss.

Additionally, the durability of digital dentures can lead to cost savings over time. Unlike traditional dentures that wear down and require frequent repairs or replacements, digital dentures are often made from high-quality materials that are more resistant to wear and tear. This means fewer visits to the dentist for repairs and less money spent on replacements. Furthermore, digital dentures can be adjusted or modified easily if necessary, eliminating the need for a complete overhaul.

In conclusion, while the upfront cost of digital dentures may be higher, their improved accuracy and fit, along with their durability, make them a wise long-term investment. Patients can enjoy the benefits of comfort, oral health, and potential cost savings in the years to come.

Proper maintenance of digital dentures is essential for ensuring their longevity and optimal performance. Here are a few tips and best practices to keep in mind:

1. Regular Cleaning: Just like traditional dentures, digital dentures require regular cleaning to prevent the buildup of plaque and bacteria. Use a soft-bristled toothbrush and non-abrasive denture cleaner to gently scrub the dentures, paying attention to all surfaces, including the gums and palate. Avoid using harsh chemicals or abrasive toothpaste, as they can damage the denture material.

2. Soaking Overnight: It is recommended to soak digital dentures overnight in a denture cleaning solution or plain water. This helps to keep them moist and prevents them from drying out, which could lead to warping or cracking. Make sure to follow the manufacturer’s instructions on the specific soaking solution to use and the duration of soaking.

Additionally, it is important to schedule regular check-ups with your dentist for professional cleaning and examination of your digital dentures. They can assess the fit and make any necessary adjustments to avoid discomfort or potential damage. By following these maintenance tips and best practices, you can ensure that your digital dentures remain in optimal condition for a longer period of time.

Innovations and advancements in the field of digital dentures are continually shaping the future of dental prosthetics. One of the key areas of development lies in the improvement of materials used in digital dentures. Researchers are exploring new materials that offer exceptional strength, durability, and natural aesthetics. These advancements aim to provide patients with dentures that not only function well but also closely resemble natural teeth in their appearance.

Another exciting innovation is the integration of artificial intelligence (AI) in digital denture design. AI algorithms can analyze vast amounts of data and generate highly accurate and customized denture designs based on the patient’s individual needs. This technology has the potential to revolutionize the way dentures are designed, manufactured, and fitted, ensuring a more precise fit and enhanced overall comfort for patients. Furthermore, AI-driven design can significantly reduce the time required for the entire denture creation process, allowing patients to receive their dentures more quickly and efficiently.

These ongoing innovations and advancements in digital dentures hold great promise for the future of dental prosthetics. With the continuous refinement of materials and the integration of AI technology, patients can expect dentures that not only provide improved functionality but also offer a more natural look and feel. Dentists and dental technicians alike are excited to embrace these advancements, as they allow for enhanced patient care and satisfaction. As technology continues to evolve, so too will the field of digital dentures, opening up an array of possibilities for a more advanced and patient-centric approach to dental care.

The future of digital dentures holds exciting possibilities, such as the integration of artificial intelligence for improved design accuracy and efficiency, the use of advanced materials for enhanced durability and aesthetics, and the development of more streamlined and automated workflows.

As technology continues to advance and become more accessible, it is likely that the cost of digital dentures will decrease over time. With increased competition and efficiency in manufacturing processes, the affordability of digital dentures may improve in the future.

Yes, researchers and developers are constantly working on improving 3D scanning technology for digital dentures. This includes advancements in accuracy, speed, and ease of use, which can contribute to a more efficient and comfortable patient experience.

Yes, one of the advantages of digital dentures is their flexibility and convenience when it comes to adjustments or repairs. With the original digital design stored electronically, adjustments can be made digitally and then manufactured accordingly, minimizing the need for physical modifications.

Digital dentures have the potential for increased durability and longevity compared to traditional dentures. The use of advanced materials and precise manufacturing processes can contribute to a longer lifespan, but individual factors such as oral health and maintenance also play a role in the overall lifespan of digital dentures.

While digital dentures are becoming increasingly popular and offer numerous advantages, it is unlikely that they will completely replace traditional dentures. Traditional dentures will still have their place, particularly for individuals with specific oral health needs or preferences that may not be accommodated by digital dent

Yes, one of the benefits of digital dentures is the ability to customize the color and shape to match the patient’s individual preferences. Digital design software allows for precise customization, ensuring that the dentures meet both functional and aesthetic requirements.

Yes, there are ongoing studies and research being conducted to evaluate the effectiveness and long-term outcomes of digital dentures. These studies aim to further validate the benefits and advantages of digital dentures in terms of fit, comfort, and patient satisfaction.

Yes, digital dentures can be used for partial denture solutions as well. The same digital design and manufacturing processes can be applied to create partial dentures that are customized to fit the specific needs of the patient.

Yes, digital dentures can have environmental benefits compared to traditional dentures. The digital workflow reduces the need for physical impressions and models, minimizing waste and the use of materials. Additionally, advancements in materials used for digital dentures may also contribute to reduced environmental impact.